Predictive Maintenance Platform

Trusted by

Sibyl Modules

Anomaly Detection

utilizing ML algorithms and state of the art techniques.

Real-time analysis of the sensors’ signals.

Detection of instant deviations from the normal operation

Detection of constantly evolving deviations

Fault Identification

Identify the failure mode of a fault with high accuracy and dependability.

Utilization of techniques that require minimal historical data footprint to identify rare events

Neural Network models to identify frequent faults

Custom made solutions for fault identification of special cases

Faults prediction

Timely be alerted of prominent faults in your mechanical

assets and prepare in advance the mitigation plan.

Fault prediction based on timeseries analysis

Fault prediction identifying re-occuring patterns of events

Adjustable prediction time span

Remaining Useful Life Estimation

Be informed constantly about the remaining life and production capabilities of your assets

Long-term health check

Accurate estimation of the remaining product cycles of operation time

Continuous optimization of estimation accuracy

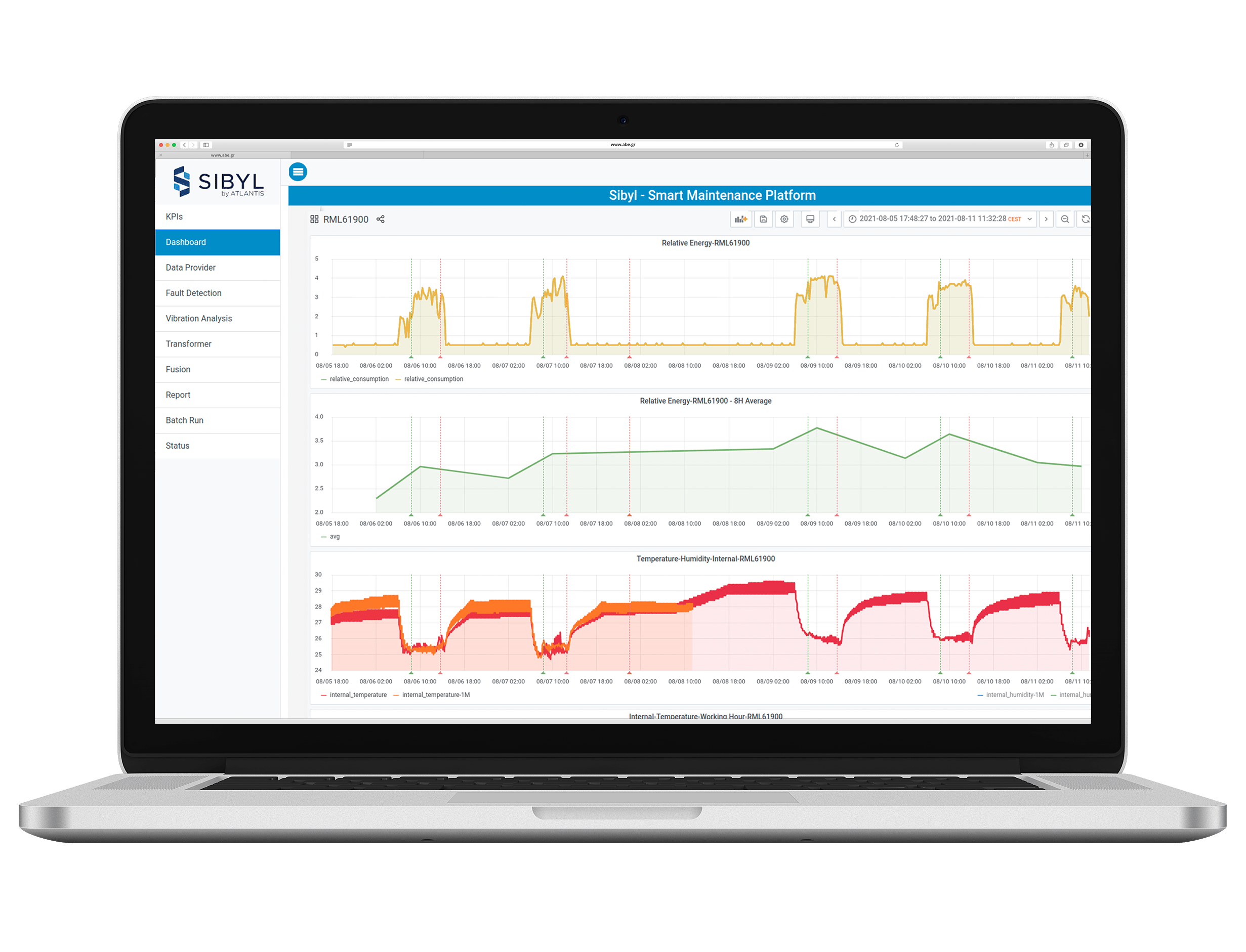

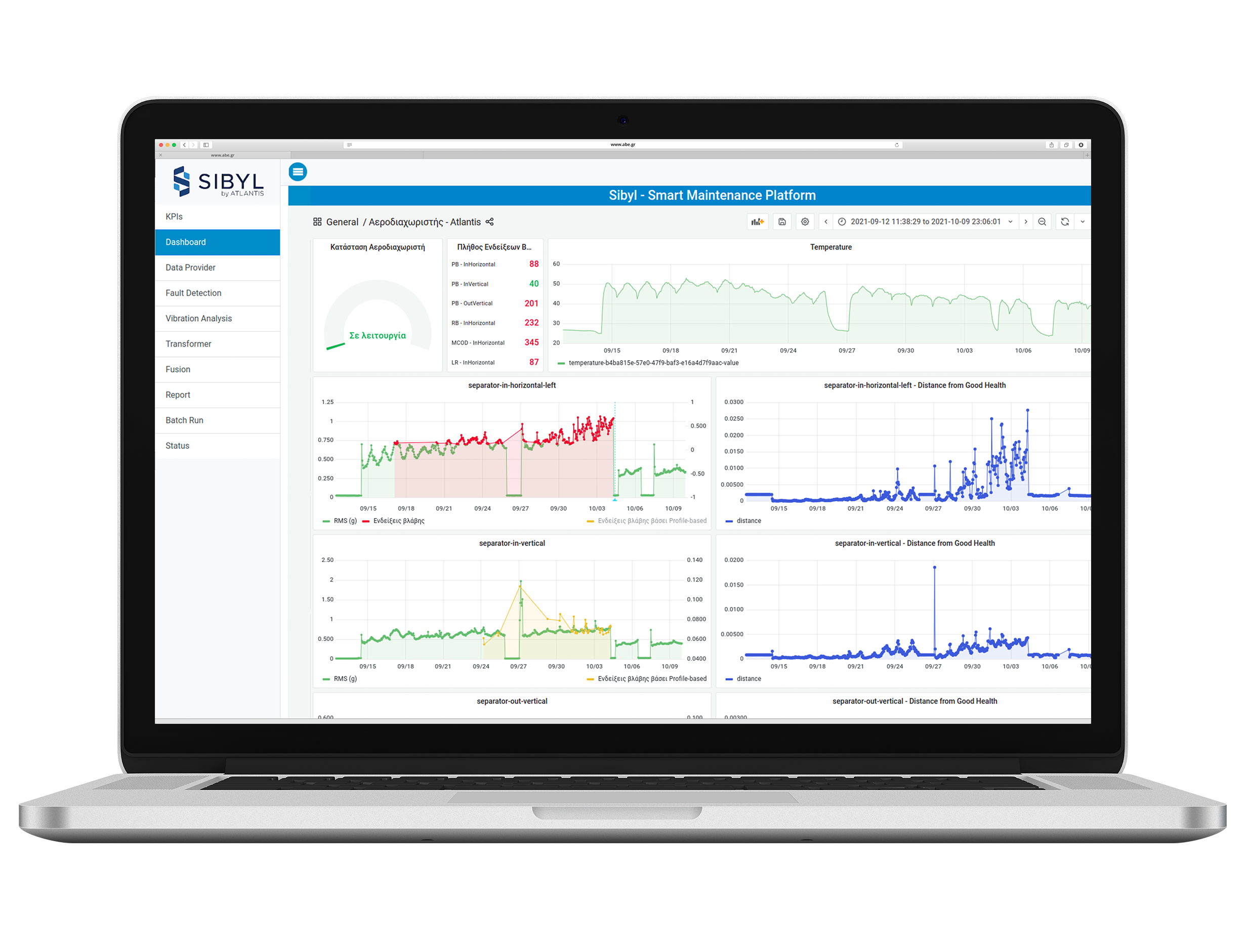

Sibyl Monitoring

Visualization

Live visual representation of the collected signals from the sensors and the state of the mechanical assets

Analysis

Comparative study on historical data

Customization

Adaptation of the user interface to the requirements of the maintenance departments

Health Indications/KPIs

Development of multi-parametric indicators for the accurate representation of the health of the assets

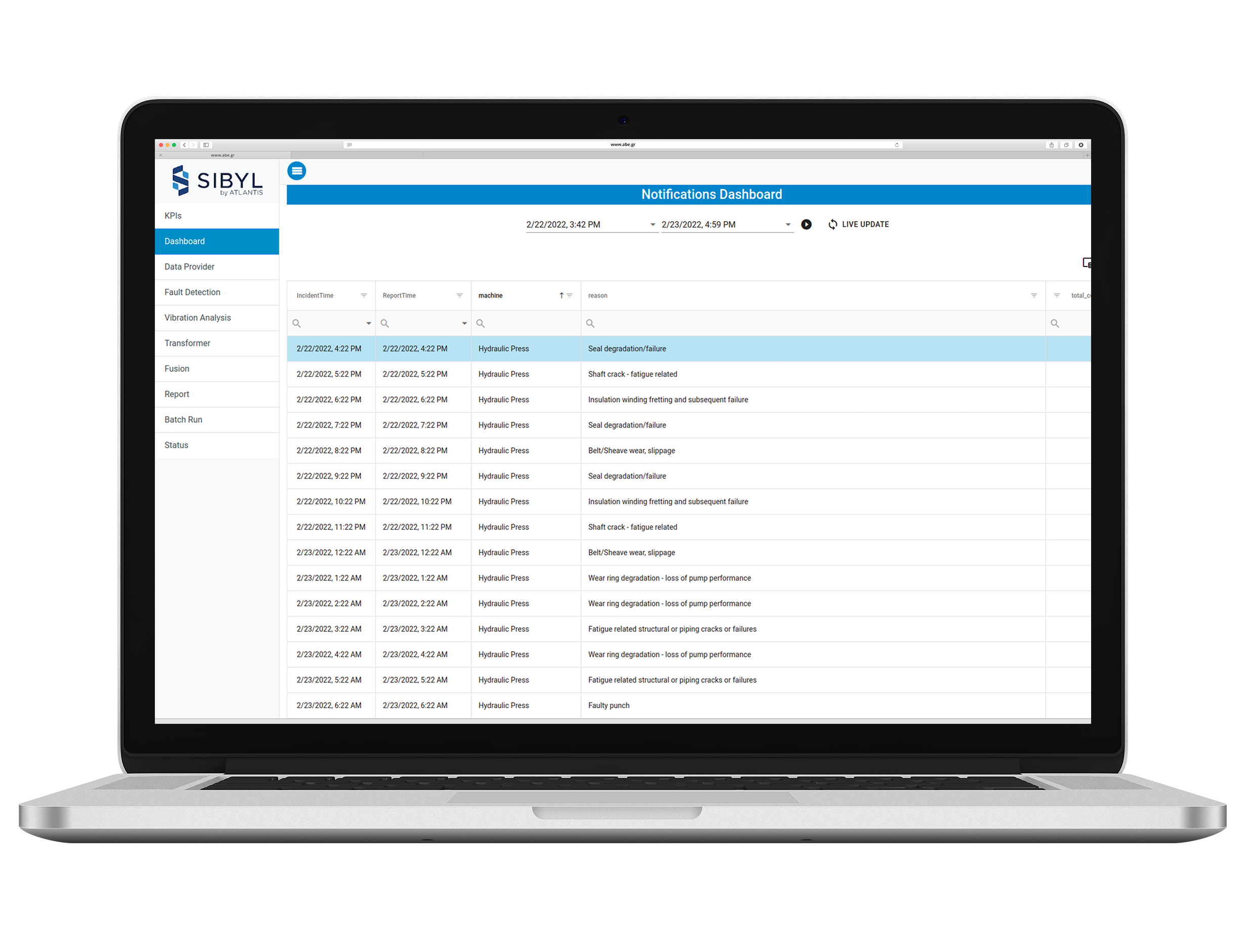

Notifications

Receive timely notifications and provide your feedback to improve the accuracy of the results

AIMMS interoperability

Automatic work order creation to the AIMMS software or other CMMS

Successful faults prediction using Machine Learning

Timely forecasts

Using powerful AI algorithms up to 72 hours before fault occurance

Downtime Reduction

Minimize downtime in the production

Custom solutions per machine

Custom algorithms for each failure mode

They said about us

Apply Sibyl and

Prevent unplanned production interruptions

Avoid unnecessary maintenance

Improve maintenance scheduling

Avoid serious failures to your assets

Increase the availability of your mechanical assets

Expand the lifespan of the mechanical assets